Zero- to Three-Dimensional Nanostructures for Application in Electronics and Renewable Energy Sources: Synthesis, Characterization and Processing

Implementation period: 01/01/2011 - 31/12/2019

GA number: III 45007

Type of Project: National

Project aim: The project included fundamental, applied and development research of 0-3D nanostructures with the purpose of developing electroceramics for application in electronics and renewable energy sources. The final goal was introduction of new materials, devices and methods into production and advancement of existing and development of new synthesis methods with the purpose of obtaining new materials, improved functional properties of materials using nanostructure precursors and development of new innovative processing methods.

About the project:

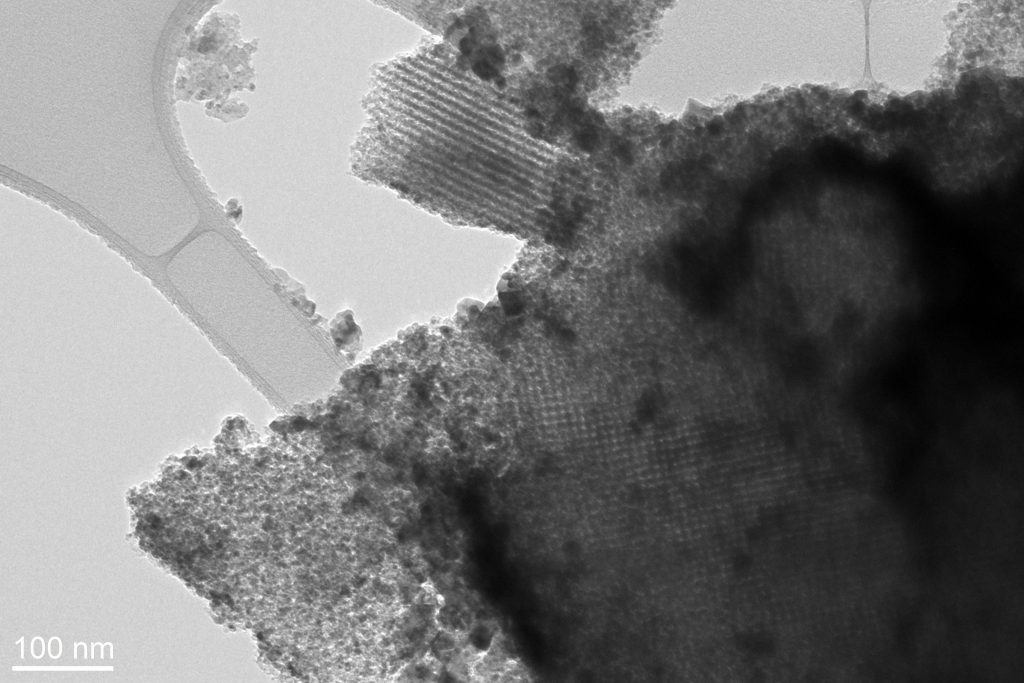

It included synthesis, characterization and processing of nanostructures based on simple or complex oxides and non-oxide inorganic substances: quantum dots (0D), nanotubes and nanowires (1D), thin films (2D) and bulk nanostructure ceramics (3D). Emphasis was on synthesis of precursor nanostructures and research of innovative processing methods in order to preserve nanostructures in final ceramics and obtain preferentially oriented or anisotropic materials. Thirty three scientists from 7 research institutions and 3 scientists from abroad participated in this project. The project was realized through 4 subprojects (SP) organized according to the type of research and application field of the investigated material: 1. Structural aspects of nano and other advanced materials, 2. Electronic materials, 3. Materials for renewable energy sources, 4. Thick film technology and microelectronics.

SP1 -provided the base for linking structure, properties and application of materials in aid of synthesizing materials with improved properties. Possible modifications and improvement of the following synthesis methods was investigated: co-precipitation, controlled diffusion, sol-gel, polymerizable complex, solvothermal synthesis and mechanochemical synthesis as well as synthesis of mesoporous metal oxides using sacrificial template method, enabled control of the chemical and phase composition on an atomic, nano, and micro -scale. All phases from reactants, via precursor to the final product, were followed by a detailed chemical, spectral and structural analysis (XRD, HRTEM, SEM, AFM, IC, UV-VIS, EPR, RS, PL, DTA etc.). Research included binary and ternary complexes of transition metals and combined compounds of transition and post-transition elements with nano or angstrem porosity. SP2 – Materials for electronics and information technology were in the form of thin and thick films or bulk ceramics. Linking equipment for electrical characterization with an optical and atomic-force microscope enabled measuring of electrical, ferroelectrical and multiferroic properties of micro and nanostructures.

SP2 included chemical synthesis and innovative methods for processing the following materials: a) nanostructures of pure and doped ZnO and TiO2; b) varistors and sensors based on doped ZnO and SnO2 nanostructures; c) ferroelectric ceramics based on (Pb,Zr)TiO3 and (Ba,Sr)TiO3; c) multiferroics BiMnO3 and BiFeO3.

SP3 included materials for renewable energy sources: 1. Solid oxide fuel cells: a) synthesis of electrolite nanopowders based on anion (Gd, Ce and Sm oxides) and proton (doped BaCeO3) conductors by autocombustion, b) production of cermet anode based on anion and proton conductors using the tape casting method, c) deposition of thick electrolite films on anode substrates using spray and tape casting methods and d) microstructure and electric characterization of anodes, electrolites and functional fuel cells. 2. Photovoltaic cells (PV) based on different TiO2 and ZnO nanostructures and the dye sensitized PVs, as well investigations of their photocatalytic properties. 3. Thermoelectrics with an increased Seebeck coefficient obtained using nanostructure materials. Research included influence of doping and morphology on thermoelectric properties of ZnO and NaCo2O4.

SP4 included obtaining and characterization of doped nano NiMn2O4 NTC powder, thick film paste, feedstock, obtaining optimized and miniaturized NTC sensors using thick film technology. Obtained NTC sensors (planar or 3D radial) were used to construct fluid sensor prototypes (water and air) for which electronic components and software was developed in order to obtain an intelligent sensor system. Thick film technology was also used to obtain gas sensors, multilayer varistors, ferroelectrics and integrated electronic components.

Themes:

1) Metal oxide nanomaterials